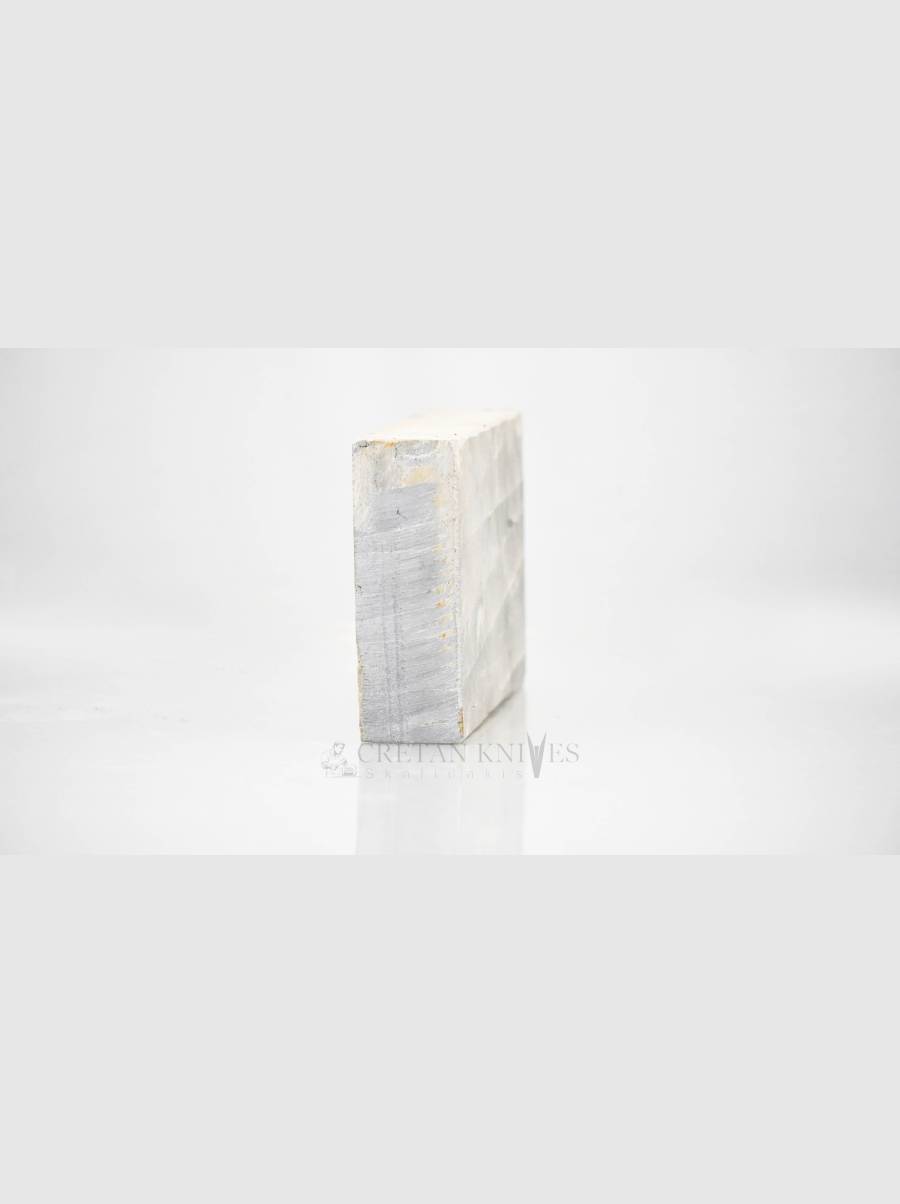

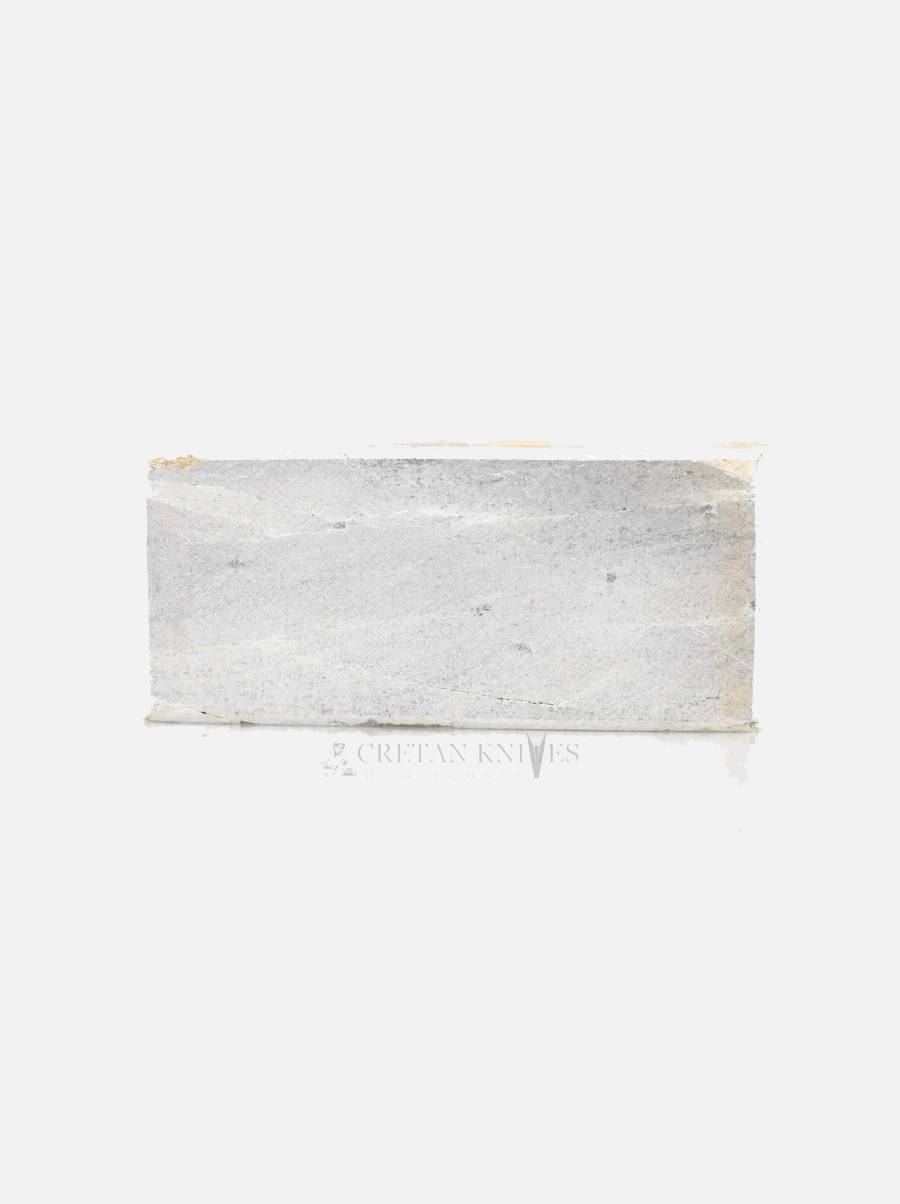

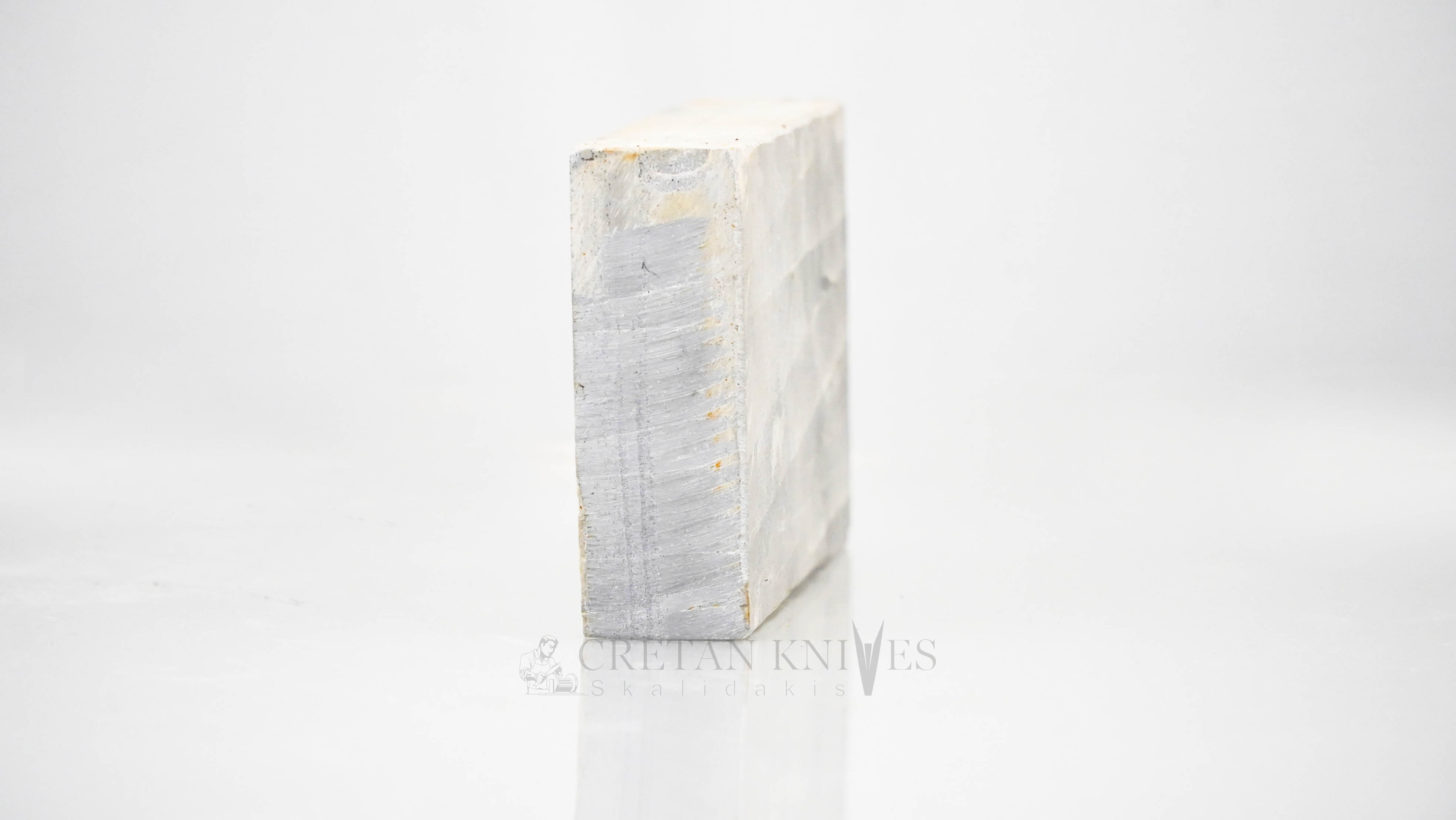

Cretan Knives Skalidakis Natural Sharpening Stone of Crete Ladakono 6000/8000 Grit

Description

Instructions

Sharpening

Maintenance

Description

Instructions

CRETAN NATURAL SHARPENING STONE – USER INSTRUCTIONS

The quality of this stone allow us to use this stone from the beginning till the finishing of every blade. It is not necessary to use bonded abrasives to start sharpening. You can use this natural stone from the start to the end of a blade complete sharpening. You must respect the following steps:

- Place some honing oil on the stone (any natural oil). Never use it dry. The oil will keep the steel shavings from clogging the pores of the whetstone.

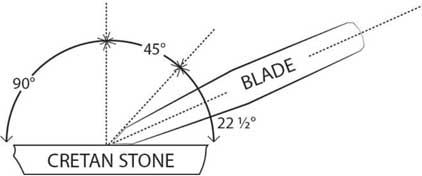

- Lay the blade across the stone as illustrated, tilting it to the desired honing angle and draw the blade across the hone in a slicing motion, sweeping the length of the hone so that the whole blade from guard to tip is passed over the hone in one motion.

- The honing angle must be kept between 20 and 30 degrees. The larger the angle the tougher the edge. Maintaining a consistent angle is the critical factor in honing your edge, too small an angle makes a weak edge which will dull rapidly. An angle much less than 20 degrees will make the edge so thin as to bend the knife edge slightly under honing pressure and there for it cannot really be made sharp.

- Turn the blade over and again tilt to the same honing angle and repeat the same motion as in step 2. Take equal numbers of strokes for each side. After your knife has been honed , clean your whetstone by applying more honing oil to it and rub with your fingers then wipe off excess oil with a clean cloth. You can wash away the remaining oil if desired with soap and water.

HISTORY AND GENERAL INFORMATION

The stone on your hands is a natural non metallic mineral composed mainly (96-99%) from SiO2 (Silicon bioxyde) in a microcrystallised form. It is extracted from mountains beside Elounda Bay. We find these stones into the form of layers of 2 to 15 cm of thickness.

The Natural sharpening stone of Crete is a mineral very rare and characteristic of the region. It is mentionned in the Iliade d’Homère as a valuable sharpening tool. It was discovered at the 18th century by French explorers. They applied to organize local extraction and they started importing this material to the South France region specially at Avignon. They have created there several factories dedicated to the elaboration and distribution of this stone.

Historical reports give to this stone the name of “Levant stone”. Italians and French customers also call the stone “Candia stone” from the traditional name of Iraklion. We can find the same chemical composition and the same stone quality at Arkansas. The stone is called Novaculite either Arkansas stone which have the same sharpening abilities with our stone.

Despite the fact that at our days most of our honing needs are fulfilled by artificial human made stones composed mainly by several carbides the true blade professionals are still remaining amateurs of our stone.

Everybody is accepting that incomparable quality of the honing procedure using our “Levant Stone”.

Extraction – Elaboration

Due to the very small quantity and the field morphology, the stone extraction is performed with traditional very simple tools without any automatism. Each stone is extracted by hand either with the use of simple handmade tools. Raw material is composed by stones of 5-50Kgrs. These blocks are loaded to special cutting machines and cut to the desired dimensions. After cutting the stones are polished using special polishing machines.

Sharpening

Use a diamond tool specially made for sharpening you’ll find in our stores, a local Cretan natural stone world known as Ladakono, water or oil in a 30 degree angle on both sides or a chew High quality maintenance of the ridge.

Maintenance

The knife needs a little care to preserve it and enjoy the edge for a long time:

- Rinse immediately after use with warm soapy water, drying in the sun or at room temperature.

- Do not use strong detergents.

- To avoid injury when drying always hold the knife by the handle to the edge.

- Do not soak knives with handles made of natural materials for a long time.

- When storing a knife make sure that the blade is not in contact with other metal objects (other knives spoons forks etc) to avoid damage and scratches on blade.

- Store knives either in a suitcase, in a knife case, in a drawer, or in a wooden or leather case suitable for knives.